Nowadays “FERRUM” S.A. is the main Polish manufacturer of the anticorrosive, extruded, three-layer, polyethylene/polyethylene co- ating on steel pipes. The coating technology allows to obtain the anticorrosive three-layer polyethylene/polyetylene coating, which consist of:

The coating is applied on steel pipes of diameters from 159 mm to 1420 mm and length from 6 m to 18 m. Properties of applied coatings comply with the following stan- dards:

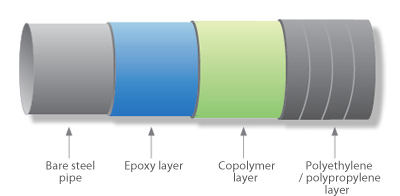

The anticorrosive coating consists of the following layers:

3,7 mm or polypropylene layer of minimal thickness between 1,8 mm and 2,5 mm.

“FERRUM” S.A. manufactures coated steel pipes in diameter from 159 mm to 1420 mm and length from 6 m to 18 m. We provide coating services with reference to pipes delivered by our custo- mers.

Coating grade |

Coating type |

Coating thickness depending on the pipe outer diameter [mm] |

||||

|---|---|---|---|---|---|---|

| 159 – 273 | 323,9 – 457 | 508 – 559 | 610 – 762 | 813 – 1420 | ||

| Polietylenowa | N-n, S-n | 2 | 2,2 | 2,5 | 2,5 | 3 |

| N-v, S-v | 2,7 | 2,9 | 3,2 | 3,2 | 3,7 | |

| Polipropylenowa | standardowa | 2 | 2,2 | 2,2 | 2,5 | 2,5 |

Note: for the diameters over 1420 mm ”FERRUM” S.A. can make coating by polyethylene tapes acc. to DIN 30672 class B30, C30 and C50.

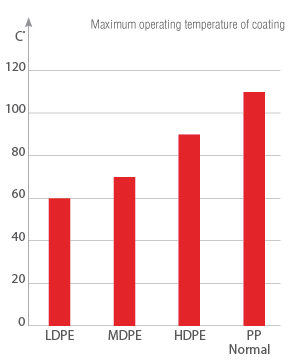

N-n, N-v coating with low density polyethylene (LDPE) or medium density polyethylene (MDPE) with regular –n and reinforced –v thickness

S-n, S-v coating with high density polyethylene (HDPE) with regular –n and reinforced –v thickness

Anticorrosive coating 3LPE/ 3LPP according to PN-EN ISO 21809-1 is composed of:

epoxy layer of minimum 125 μm thickness,

copolymer layer of minimum 150 μm thickness,

polyethylene or polypropylene layer from 1,8 mm to 4,7 mm.

Layer thickness

g/m |

Class A1 |

Class A2 |

Class A3 |

Class B1 |

Class B2 |

Class B3 |

Class C1 |

Class C2 |

Class C3 |

|---|---|---|---|---|---|---|---|---|---|

| ≤15 | 1,8 | 2,1 | 2,6 | 1,3 | 1,8 | 2,3 | 1,3 | 1,7 | 2,1 |

| 15≤ C ≤50 | 2,0 | 2,4 | 3,0 | 1,5 | 2,1 | 2,7 | 1,5 | 1,9 | 2,4 |

| 50≤ C ≤130 | 2,4 | 2,8 | 3,5 | 1,8 | 2,5 | 3,1 | 1,8 | 2,3 | 2,8 |

| 130≤ C ≤300 | 2,6 | 3,2 | 3,9 | 2,2 | 2,8 | 3,5 | 2,2 | 2,5 | 3,2 |

| 300 < C | 3,2 | 3,8 | 4,7 | 2,5 | 3,3 | 4,2 | 2,5 | 3,0 | 3,8 |

The coating manufacturing process consists of the following operations:

the surface blast cleaning to Sa 2 1/2 acc. to ISO 8501-1,

the electrostatic spraying of epoxy powder onto a heated pipe,

wrapping a pipe with extruded copolymer,

wrapping a pipe with polyethylene/polyetylene in continuous way,

cooling the coating and dressing the pipe ends.

An extruded polyethylene coating has higher mechanical properties in comparison with cold applied polyethylene tape coating. Anticor- rosive coatings made of three-layer PE/PP are characterized by:

high mechanical strength,

high adherence of the coating to the pipe,

guaranteedlong-lastinganticorrosiveprotectionofundergroundpipelines for minimum 50 years,

100% protection of weld zone of coated longitudinally and spirally welded pipes,

suitability for bending of coated steel without damaging the insulation layer.

FERRUM S.A.

ul. Porcelanowa 11

40-246 Katowice, Poland

tel.: +48 32 730 47 99

fax: +48 32 730 46 77

email: ferrum@ferrum.com.pl