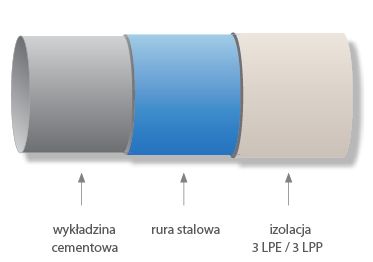

The technological process of internal cement lining assures anti- corrosion protection and stability of hydraulic parameters of pipe- lines for water and sewages and allows manufacturing products that meet all the requirements demanded by customers and inter- national standards.

Applications:

Steel pipes and fittings with cement lining are used for raw and potable water supply pipelines as well as for sewage system for both municipal and industrial effluents. These pipe systems assure cost effective and ecological solutions, due to material and energy saving in terms of extension of their working life and environmen- tally friendly technology.

Advantages of cement lined steel pipes and fittings:

Technical data:

We make cement mortar lining for steel pipes of diameters from 159 mm to 2032 mm, length from 6 m to 18 m, according to the conditions specified into the following standards:

Thickness of cement lining on pipes acc. to DIN 2614 for method II

Nominal diameter |

Thickness of layers [mm] |

||

|---|---|---|---|

From |

To |

Minimum layer |

Maximum individual layer thickness |

| 150 | 300 | 4 | 9 |

| 300 | 600 | 5 | 10 |

| 600 | 900 | 6 | 13 |

| 900 | 1200 | 8 | 15 |

| 1200 | 12 | 19 | |

Thickness of cement lining on fittings acc. to DIN 2614 for either method II or III

Nominal diameter |

Thickness of layers [mm] Layer thickness |

|||

|---|---|---|---|---|

From |

To |

Nominal thickness |

Minimum layer thicknes |

Maximum layer thickness |

| 300 | 5 | 3 | 10 | |

| 300 | 600 | 7 | 5 | 10 |

| 600 | 900 | 10 | 8 | 12 |

| 900 | 1200 | 12 | 10 | 15 |

| 1200 | 15 | 12 | 19 | |

FERRUM S.A.

ul. Porcelanowa 11

40-246 Katowice, Poland

tel.: +48 32 730 47 99

fax: +48 32 730 46 77

email: ferrum@ferrum.com.pl